Wastewater Operations

Wastewater Treatment Process Overview

When you flush your toilet or use the sink or shower, the water that goes down the drain flow through the sewer system to one of the Juneau’s three wastewater treatment plants. The treated liquid portion is returned to a local waterbody, but the solid phase (known as biosolids) is treated separately. While MTP, JDTP and ABTP each use different technology and equipment to treat wastewater, the principles and stages of treatment are the same:

- preliminary treatment (headworks) removes large debris, solids, and grit;

- secondary (biological) treatment utilizes microbes to break down waste products;

- disinfection inactivates any remaining pathogenic organisms in the liquid stream before discharging;

- solids handling includes separating the solids from the liquid stream and dewatering (removing free liquid) in preparation for disposal.

See the biosolids page for more information about biosolids treatment and disposal.

Facility Information

The residents, businesses, and tourists to the City and Borough of Juneau are serviced by approximately 7,150 sewer connections via a network of roughly 140 miles of pipes and 45 lift stations known as the Collections System. The sewer collection lines convey the flow to one of the three treatment plants (Juneau-Douglas WWTP, Mendenhall WWTP, or Auke Bay WWTP) located throughout CBJ which processes nearly 3.3 million gallons per day (MGD) or roughly 1.2 billion gallons of water annually.

Wastewater Collection System Operations and Maintenance

The City and Borough of Juneau Wastewater Collection System is complex system of underground pipes and pumps designed to transport human waste, storm water, and industrial waste from its source to treatment facilities. This system consists of 140 miles of gravity sewer mainlines, ranging in size from 6 to 30 inches in diameter (seventy-five percent of the system consists of 8-inch mains). The system also has approximately 2,776 manholes, 45 pump lift stations and serves approximately 7,150 customers. In addition to the piping, there are numerous service laterals, tap connections, pipe joints, interceptors, cleanouts, vaults, pump lift stations, creek crossings, inverted siphons, bar racks, and vent pipes-all of which are integral parts of the wastewater collection system. Because the system is entirely interconnected, each of these components affects the whole system and therefore they must be rigorously monitored and maintained.

WWU Boomtruck in Action

The fluid waste distributed through this system is about 98% water. The waste floats on, is carried along by, and goes into suspension or solution in water. Possible waste includes anything that can be flushed down the drain–human excretion, body fluids, paper products, soaps and detergents, foods, fats, oil, grease, paints, chemicals, hazardous materials, solvents, disposable and flushable items; the list is almost infinite. This mixture of water and wastes is called “wastewater.” In the past, it was known as “sewage,” but this term is now falling out of favor because it refers specifically to domestic sanitary wastewater, like toilet flushing, which represents only a portion of the entire fluid waste content. “Wastewater” is a more accurate description and has become the standard term for this fluid waste because it encompasses the total slurry of wastes in water that is gathered from homes and businesses.

Lift Station Pumps

Every house, restaurant, business and industry produces waste. Wastewater collection protects public health and the environment by removing this infectious waste and recycling the water. A network of interconnected pipes accepts the flow from each building’s sewer connection and delivers it to the treatment facilities. In addition to what homes and businesses flush down the drain, the system also collects excess groundwater, infiltration liquids, and inflow water. Wastewater collection is therefore a comprehensive liquid waste removal system.

As the city and borough continues to grow, the wastewater collection system does as well. New systems are extended and older systems are improved in coordination with capital improvement projects. The maintenance of this system is therefore a continuous, never-ending cycle. As sections of the system age, problems such as corroded concrete pipe, cracked tile, lost joint integrity, grease and heavy root intrusion must be constantly monitored and repaired. Technology has improved collection system maintenance with such tools as television camera assisted line inspection equipment, jet-cleaning trucks, and improvements in pump design.

Jet-Cleaning Truck

TV-Assisted Pipe Inspector |

Control Console for the TV-Assisted Unit |

Because of the increasing complexity of wastewater collection systems, collection system maintenance is evolving into a highly skilled trade. Collection system operators are charged with protecting public health and the environment and therefore must have documented proof of their certifications in the respective wastewater management systems. These professionals ensure that the system pipes remain clear and open. They eliminate obstructions and are constantly striving to improve flow characteristics. They keep the wastewater moving, underground, unseen, and unheard. Because this wastewater collection system and the professionals who maintain it operate at such a high level of efficiency, problems are very infrequent. So much so that the public often takes the wastewater collection system for granted. In truth, these operators must work hard to keep it functioning properly.

The Juneau Wastewater Collection crew currently has eight members who are responsible for the entire wastewater collection system. These operators are required to be on a rotational on-call duty 7 days a week, 24 hours a day, thus providing the community with an operator 365 days a year to respond to any and all emergencies that may occur.

Combined Sewer Overflows

Historically, the Wastewater Utility found it necessary to divert a combination of domestic sewage and storm water to Gastineau Channel. These events are called Combined Sewer Overflows (CSOs). CSOs occur when the sewer system experiences extremes in flow, usually caused by heavy rains. Though very infrequent, CSOs can also be caused by equipment failures, such as a leak developing in the pressure sewer between the pump station and the treatment plant.

A CSO is manually initiated by the crews, usually when either the storage capacity of the sewer collection system is exceeded or when the flow of wastewater through the treatment plant has become too high to properly treat it.

Water being diverted is routinely very dilute because is is made up primarily of storm water. Still, these events are kept as short in duration as possible. This water is also quantified and tested. This means that the amount and composition is tracked as required by the Environmental Protection Agency (EPA).

Following is a list of public notices since 2004 in an effort to make the public aware of these events and to fully comply with the EPA discharge permit.

No Combined Sewer Overflow since 2005.

2005 Combined Sewer Overflow Notices

Nov 18, 2005 City Hall

Nov 21, 2005 City Hall

2004 Combined Sewer Overflow Notices

September 2004

Juneau-Douglas Treatment Facility

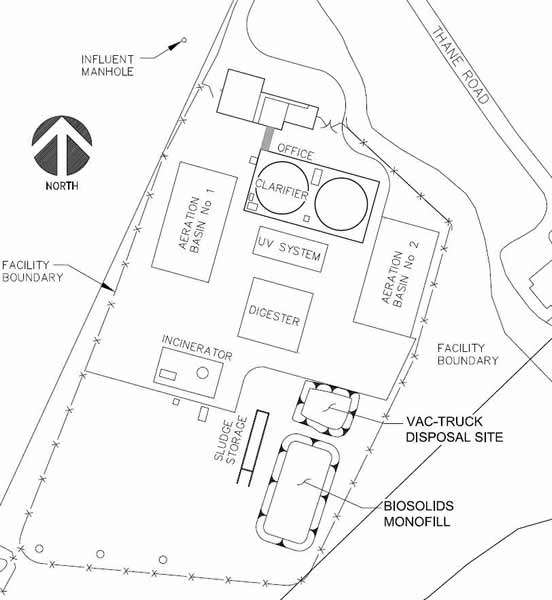

The Juneau-Douglas Wastewater Treatment Plant (JDTP) was constructed in the early 1970’s. It is located approximately two miles south of downtown Juneau at 1540 Thane Road, Juneau, AK, 99801. The plant is a conventional flow-through activated sludge treatment plant. JDTP discharges treated wastewater effluent directly to the Gastineau Channel at latitude 58° 17’ 02” N and longitude 134° 23’ 13” W under NPDES Permit No. AK-002321-3 and is subject to the requirements of the Clean Water Act (33 U.S.C.) and a National Pollutant Discharge Elimination System permit (40 CFR 136). Additionally, JDTP has been permitted for an occasional combined sewer overflow (CSO) as a result of a high tide or precipitation event.

Plant Information – Site Plan

Process Flow Diagram

Additional Information:

- Operation and Maintenance Plan

- ADEC Effluent Discharge Permit

- September 15, 2014 ADEC Inspection Report

- Monofill Permit

- Historical Archive

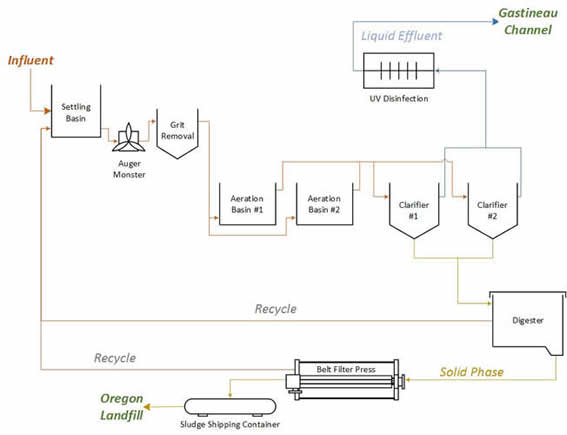

Mendenhall Treatment Facility

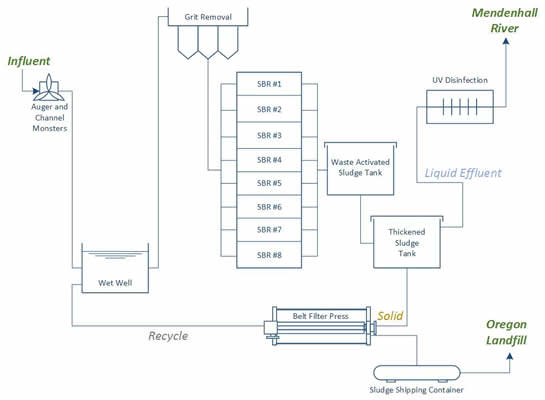

The Mendenhall Wastewater Treatment Plant (MWWTP) was constructed in the 1960’s. It is located roughly seven miles north of downtown Juneau at 2009 Radcliffe Road, Juneau, AK, 99801. The original activated biofilter plant was upgraded to a sequencing batch reactor facility in 1989. MWWTP discharges treated wastewater effluent through a diffuser system to the Mendenhall River at latitude 58° 21’ 48” N and longitude 134° 20’ 08” W under NPDES Permit No. AK-002295-1 and is subject to the requirements of the Clean Water Act (33 U.S.C.) and a National Pollutant Discharge Elimination System permit (40 CFR 136).

Mendenhall Plant Location

Mendenhall Plant Process Flow Diagram

Additional Information:

- Sequencing Batch Reactor Technology

- Operations and Maintenance Plan

- Quality Assurance Master Plan

- ADEC Effluent Discharge Permit

- November 19, 2014 AKOSH Unprogrammed Inspection Letter

- Historical Archive

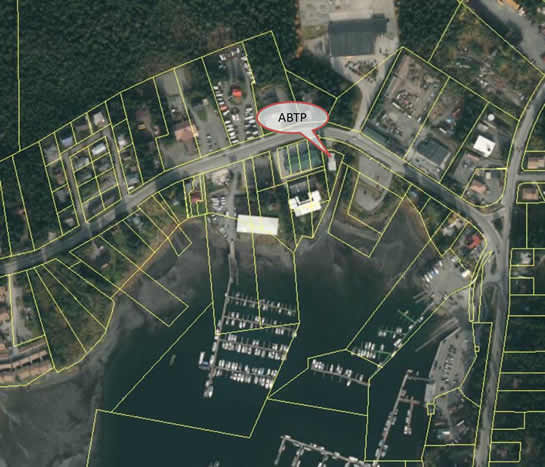

Auke Bay Treatment Facility

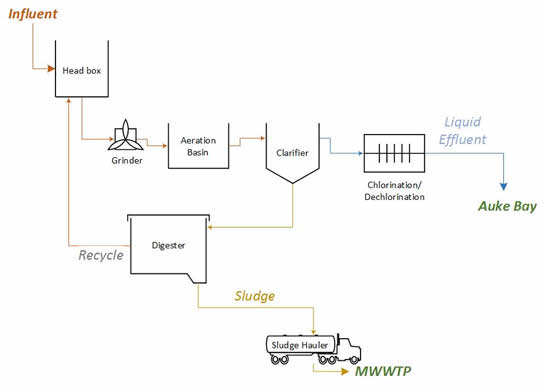

The Auke Bay Wastewater Treatment Plant (ABTP) was constructed in the late 1970’s. It is located roughly ten miles north of downtown Juneau at 11825 Glacier Highway, Juneau, AK, 99801. The activated sludge secondary treatment package plant discharges treated wastewater effluent into Auke Bay at latitude 58° 23’ 06” N and longitude 134° 38’ 55” W under NPDES General Permit No. AKG572000 and is subject to the requirements of the Clean Water Act (33 U.S.C.) and a National Pollutant Discharge Elimination System permit (40 CFR 136).

Auke Bay Plant Location:

Auke Bay Plant Process Flow Diagram:

Additional Information:

- Operations and Maintenance Plan

- ADEC Effluent Discharge Permit

- September 17, 2014 ADEC Inspection Report

- Historical Archive

Historical Information

Juneau’s first wastewater treatment facility was a 0.02 million gallons per day (MGD) secondary package plant located in the Mendenhall Valley at 2009 Radcliffe Road built in the mid-1960s known as the Mendenhall Wastewater Treatment Plant (MWWTP). As the valley population has grown, CBJ has upgraded several times to the current SBR plant. The current conventional activated sludge treatment plant for the downtown area and Douglas went online in 1974 as the Juneau-Douglas Treatment Plant (JDTP). And a package treatment plant currently serving the Auke Bay area (ABTP) went online in 1977.