What Are Biosolids?

Biosolids are the nutrient-rich solid product from the wastewater treatment process. They are rich in organic matter, carbon and nutrients, but require thorough treatment and monitoring to be disposed of or reused.

Project Background

With the 2010 failure of the wastewater solids incinerator, CBJ Engineering and Public Works implemented a variety of disposal methods for the nearly 7,000 wet tons of biosolids generated in Juneau each year.

Currently, biosolids are containerized, barged to Seattle and hauled by train to Oregon where they are ultimately dumped into a landfill. As landfilling was only intended to be a temporary fix, CBJ Engineering and Public Works embarked on an extensive multi-year investigation to identify a long-term biosolids treatment and disposal solution.

Numerous alternatives were analyzed by CBJ staff and consultants. The results of the investigation determined that a biosolids dryer was the most economical and feasible choice for Juneau over a 20-year period. In February 2016, the CBJ Assembly Committee of the Whole approved moving forward with the dryer as the final biosolids treatment solution.

Why Drying?

In addition to cost effectiveness of a biosolids dryer over other treatment and disposal alternatives, drying creates a product with a very high reuse value.

Even after removing the free water from biosolids (dewatering) using a belt filter press, CBJ biosolids are still 85-90% water. Water adds a significant amount of volume and weight to the biosolids, making storage, transportation and reuse difficult. In addition, the dewatered biosolids may still contain pathogens, making them unsafe for reuse. A biosolids dryer, essentially a low temperature oven, evaporates most of the remaining water while deactivating any remaining pathogens. The resulting product (now only 10% water), has much less volume which allows for easier storage, transportation, and may be reused in a variety of ways.

From left to right: Untreated sewage sludge; dewatered biosolids cake (currently what CBJ ships out-of-state); dried biosolids (sample collected from dryer site visit)

Reuse Options

Biosolids are nutrient and carbon rich, making them ideal for fertilizer, erosion control or even as a fuel source. The organic matter in biosolids improves soil structure and water retention, while releasing nutrients slowly. Due to their high BTU value, biosolids may also be a candidate for use in biomass boilers or pellet stoves.

CBJ Utilities is currently analyzing feasible reuse options for the dried biosolids pellets in Juneau. A preliminary report of the options has been completed.

Project Description

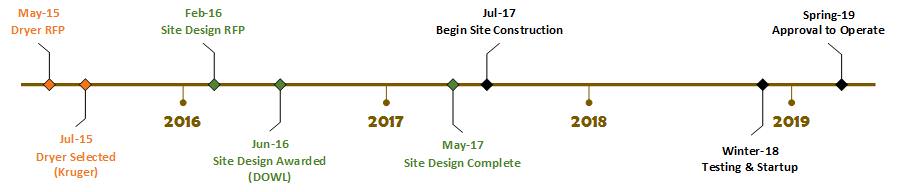

In 2015, a Request for Proposals (RFP) was issued for a biosolids dryer manufacturer. Kruger Inc. had the winning bid. Working with Kruger, DOWL engineers are designing the new dryer facility which will include the dryer, storage tanks, a bagging station for the pellets, a small laboratory, and control room.

The facility will be located at the Mendenhall Wastewater Treatment Plant in the old ABF Building site. A new building will be constructed on the site. The original foundation and some of the storage tanks will be reused for the dryer facility. Odor control equipment will be installed at the dryer facility as well as the headworks facility (pending funding).

This project will be funded through the Alaska Clean Water Fund loan program and CBJ Utilities rate revenue.

Updates

- 3/30/2017-Biosolids Public Information Session scheduled for April 27th, 6pm-7:30pm in the Alaska Room at the Airport (free parking provided). All members of the public are invited to attend this meeting. We will have a short presentation overviewing the biosolids project and upcoming dryer installation, followed by a Q&A session.

- 3/1/2017-The dryer is currently in the design phase. Preliminary site work is being completed to prepare for construction this summer. The project schedule is shown below.

Frequently Asked Questions

- What are biosolids?

Biosolids are the solid product from of treating wastewater from homes and businesses. Solids are separated from the liquid portion of wastewater and treated. - What’s the difference between sewage sludge and biosolids?

The term “sludge” is generally used for wastewater solids that are untreated. Biosolids are treated sewage sludge. - What do biosolids look like?

Dewatered sludge cake looks a lot like wet modeling clay and is about 10-15% solid matter. When dried, biosolids look like dark soil. - Do biosolids have an odor?

Treated biosolids generally have an “earthy” smell similar to bone meal or manure. - Where and how are biosolids used?

Biosolids are reused as fertilizer and in other applications in all 50 states. Farming fertilizer is the primary reuse method, but biosolids are used in many other ways as well: land reclamation, forestry, erosion control, and in some cases, in place of wood in biomass burners or pellet stoves. - Are biosolids safe?

Whether disposed or reused, all biosolids are subject to rigorous regulation from the EPA. Biosolids that are land applied in any way must also undergo frequent testing for pathogens, metals and must meet odor requirements.Biosolids that meet the strictest EPA guidelines can be used to fertilize food crops and home gardens. - What are the regulations for land application of biosolids?

The federal biosolids rule is part of 40 CFR Part 503. Any land applied biosolids must meet strict regulations and quality standards for pathogen reduction, metals content, record keeping and reporting requirements. A guide to the regulations can be found here. - What’s the different between Class A and Class B biosolids?

Class A and Class B biosolids are terms used by the EPA to distinguish between different levels of pathogens remaining in the biosolids after treatment. Class A meets stricter pathogen limits than Class B, so they pose less risk to the public and may be used in a greater variety of ways. Class A Exceptional Quality (EQ) biosolids go a step further and meet additional pollutant and odor limits set by the EPA. - What about the quality of CBJ’s biosolids?

Once the dryer is complete, CBJ’s biosolids will meet the EPA’s strictest guidelines for treatment, Class A EQ, and will be safe to use on lawns, gardens and other land application methods. More information about CBJ’s biosolids quality can be found here. - How is this project funded?

The CBJ’s dryer will be funded through the Alaska Clean Water Fund loan program and CBJ Utilities rate revenue. - Will the dryer save money?

Yes. Over a 20 year period, the dryer will save the Wastewater Utility an estimated $900,000 annually in operation and maintenance costs from the status quo of shipping out-of-state. More detailed information on the cost study is available here. - What about odor from the dryer?

Odor control has been included in the project. The dryer facility will be equipped with odor control equipment. - Will the dryer be noisy?

Surprisingly, no! CBJ staff toured several facilities with the same types of dryers and they were reasonably quiet. Two people could easily carry on a conversation in the building while these Kruger brand dryers were running. - I still have more questions/concerns. Who can I contact?

We would love to hear from you. Please use our contact page to get in touch with the CBJ Utilities Division with any questions or concerns related to this project, or others.

CBJ Biosolids Treatment and Disposal Project Investigations

Tetra Tech Phase I Evaluation

CH2M Hill Phase II Evaluation

Biosolids End Use Analysis

CBJ Biosolids Presentations

Biosolids Public Information Session

Regulations

EPA Part 503 Rule

EPA Biosolids Website

ADEC Biosolids Regulations

Additional Resources

NACWA Banking on Biosolids

NEBRA Biosolids Survey

Northwest Biosolids Website